New Product Introduction (NPI)

You just designed this great new product. Now you want to bring it to market with the least delay, manufactured at the lowest cost and working to spec reliably. That is UMAI’s #1 strength.

Every NPI has DFM (Design For Manufacturing) problems. From design issues, to sourcing the right components at the right price and delivery. And DFT (Design For Test) problems, like inaccessible test points or too complex and expensive functional test. Those are the facts in the manufacturing business. A large CM or EMS mostly does volume production. And any NPI they do is for sophisticated OEMs. They are just not setup to hand-hold small OEMs through their NPI problems. But those are the majority of UMAI’s customers, what UMAI is setup for, and hence excels at.

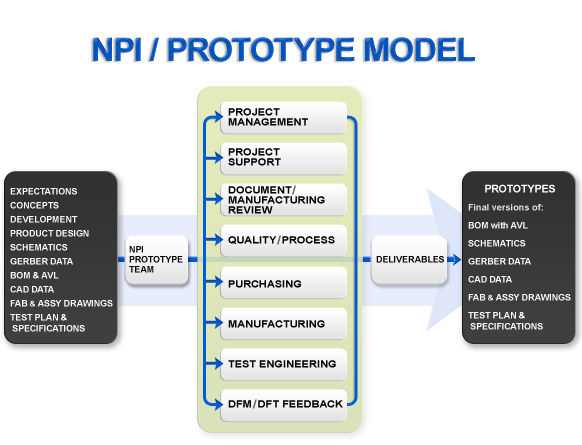

The NPI/Prototype Model below shows the steps. Many in the industry have a similar process. The difference is UMAI’s responsiveness and caring in going about these steps: We do what it takes to make your NPI successful – just read the many reference letters stating that.